| Job: | LIDL Moore Street, Dublin, Ireland |

| Main Contractor: | Monami Construction |

| SMET Products Used: | Bauprotec 850 M – Lime Cement Render |

Related Downloads |

|

DescriptionSmet Supported Partner, Nomami Construction machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render, and as Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render. The internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. Monami Construction completed the refurbishment oft this existing LIDL Store on Moore Street, Dublin. This project involves the refurbishment of the existing store and the construction of a new warehouse and staff area in the basement level under the store. The entire scope of works included: New Basement Level 1. New warehouse. 2. New stairs from basement level to store level. 3. New good lift from basement level to store level. 4. New staff room and kitchen. 5. New training room. 6. New welfare facilities. Existing Store 1. New openings to facilitate the new goods lift and access stairs 2. Extending of the existing bakery freezer and preparation area. 3. Extending of the existing cash office. 4. Extending of the existing public welfare facilities. 5. Reduction of the existing warehouse at ground floor level 6. Extension of the entrance area. 7. Modifications and upgrading of the entrance off the public street. The project was completed in October 2017 SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job – contact SMET on. All LIDL spec SMET Render System products are available directly from Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|

| Job: | LIDL Rathfarnham, Ireland |

| Main Contractor: | NRS Group |

| SMET Products Used: | Bauprotec 850 M – Lime Cement Render |

Related Downloads |

|

DescriptionSmet Supported Partner, NRS Group machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render, and as Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render. The internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas, and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job – contact SMET on. All LIDL spec SMET Render System products are available directly from Smet Building Products Ltd, which ensures the contractor has a superior level of technical backup in the machine application of the LIDL specification. |

|

| Job: | LIDL Wilton Cork, Ireland |

| Main Contractor: | NRS Group |

| SMET Products Used: | Bauprotec 850 M – Lime Cement Render |

Related Downloads |

|

DescriptionSmet Supported Partner, NRS Group machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render, and as Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render. The internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used.

SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job – contact SMET on. All LIDL spec SMET Render System products are available directly from Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|

| Job: | LIDL Portmarnock, Ireland |

| Main Contractor: | McCaliion Group |

| SMET Products Used: | Bauprotec 850 M – Lime Cement Render |

Related Downloads |

|

DescriptionSmet Supported Partner, Mc Callion Group, machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render, and as Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render. The internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. Here’s the McCallion Group in action:

The LIDL render spec, available from SMET consists of: Bauprotec 850 M is a factory produced Lightweight Lime Cement Render, specially designed for machine or hand application produced to EN 998-1: 2010 and is CE Marked. Bauprotec RHS is a CE Marked, factory produced highly polymer-modified render specially designed for hand and machine application produced to EN 998-1: 2010. Mineral Finish Coat – K is a CE marked, factory produced mineral based, high-quality finish-coat render, specially designed for hand and machine application to EN 998-1, 2010. Bauprotec SLP is a CE Marked, factory produced Lightweight Sand & Cement Render specially designed for hand and machine application produced to EN 998-1: 2010. The special render properties; lightweight, low thermal conductivity, high yield and Smet Supported Partner superior technical backup, are key factors in choosing SMET. SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job – contact SMET on. All LIDL spec SMET Render System products are available directly from Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|

| Job: | LIDL Drogheda, Ireland |

| Main Contractor: | Relwal (John Lawler Plastering) |

| SMET Products Used: | Bauprotec 850 M – Lime Cement Render |

Related Downloads |

|

DescriptionSmet Supported Partner, Relwal Plastering machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render, and as Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render. The internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. The LIDL render spec, available from SMET consists of: Bauprotec 850 M is a factory produced Lightweight Lime Cement Render, specially designed for machine or hand application produced to EN 998-1: 2010 and is CE Marked. Bauprotec RHS is a CE Marked, factory produced highly polymer-modified render specially designed for hand and machine application produced to EN 998-1: 2010. Mineral Finish Coat – K is a CE marked, factory produced mineral based, high-quality finish-coat render, specially designed for hand and machine application to EN 998-1, 2010. Bauprotec SLP is a CE Marked, factory produced Lightweight Sand & Cement Render specially designed for hand and machine application produced to EN 998-1: 2010. The special render properties; lightweight, low thermal conductivity, high yield and Smet Supported Partner superior technical backup, are key factors in choosing SMET. SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job – contact SMET on. All LIDL spec SMET Render System products are available directly from Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|

| Job: | LIDL Macroom, Cork, Ireland |

| Main Contractor: | Raymur Construction |

| SMET Products Used: | Bauprotec 850 M – Lime Cement Render |

Related Downloads |

|

DescriptionSmet Supported Partner, Raymur Construction machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render, and as Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render. The internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. The LIDL render spec, available from SMET consists of: Bauprotec 850 M is a factory produced Lightweight Lime Cement Render, specially designed for machine or hand application produced to EN 998-1: 2010 and is CE Marked. Bauprotec RHS is a CE Marked, factory produced highly polymer-modified render specially designed for hand and machine application produced to EN 998-1: 2010. Mineral Finish Coat – K is a CE marked, factory produced mineral based, high-quality finish-coat render, specially designed for hand and machine application to EN 998-1, 2010. Bauprotec SLP is a CE Marked, factory produced Lightweight Sand & Cement Render specially designed for hand and machine application produced to EN 998-1: 2010. The special render properties; lightweight, low thermal conductivity, high yield and Smet Supported Partner superior technical backup, are key factors in choosing SMET. SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job – contact SMET on. All LIDL spec SMET Render System products are available directly from Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|

| Job: | LIDL Cabra Ireland |

| Main Contractor: | Adston Construction Ltd |

| SMET Products Used: | Bauprotec 850 M – Lime Cement Render |

Related Downloads |

|

DescriptionSmet Supported Partner, Adston Construction Ltd, machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render, and as Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render. The internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. The LIDL render system, available from, SMET consists of: Bauprotec 850 M is a factory produced Lightweight Lime Cement Render, specially designed for machine or hand application produced to EN 998-1: 2010 and is CE Marked. Bauprotec RHS is a CE Marked, factory produced highly polymer-modified render specially designed for hand and machine application produced to EN 998-1: 2010. Mineral Finish Coat – K is a CE marked, factory produced mineral based, high-quality finish-coat render, specially designed for hand and machine application to EN 998-1, 2010. CASEA Bauprotec SLP is a CE Marked, factory produced Lightweight Sand & Cement Render specially designed for hand and machine application produced to EN 998-1: 2010. The special render properties; lightweight, low thermal conductivity, high yield and Smet Supported Partner superior technical backup, are key factors in choosing SMET. SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job – contact SMET on. All LIDL spec SMET Render System products are available directly from Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|

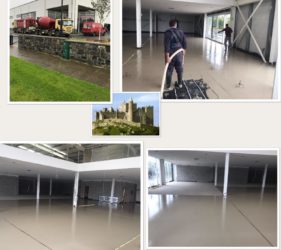

| Job: | Colm Hanley Motors Ltd, Co Tipperary |

| Smet Supported Partner: |

Fast Floor Screed Ltd |

| Product: | Südanit 280 Alpha Hemihydrate Screed Binder |

Related Downloads

Description |

|

| Smet Supported Partner, Fast Floor Screed Ltd, pump-applied 400m2 self-levelling, CE Certified Südanit 280 Alpha Hemihydrate Screed floor screed over UFH, in the commercial/industrial premises of Colm Hanly Motors Ltd, Cashel, Co Tipperary. The delivery, completed using their mobile screed factory, enabled the Alpha Hemihydrate flooring solution to be installed quickly and efficiently over the entire project, reducing downtime for Colm Hanly Motors. This CE marked,

This CE marked, self-smoothing, self-levelling screed is the most technologically-advanced floor screed available, complying with the performance requirements of EN 13813. Südanit 280 Alpha Hemihydrate Screed’s advanced composition means that it reacts with water quickly – providing consistent, reliable drying characteristics and considerably faster drying times – enabling following trades to proceed without delay.

The floor is remarkably quick to walk-on – applied at 500m² per day and walkable within in 6 hours and it’s particularly suitable for use with UFH, fully encapsulating pipes and services – increasing the performance of underfloor heating. Smet Building Products Ltd in partnership with Fast Floor Screed Ltd, demonstrate, once again, a superior level of customer service, both pre and aftercare. Whether your job is self-build, retro-fit, floor renovation, design, commercial or an industrial venture – we have a floor compound suitable for you. Contact Smet Building Products Ltd See the Fast Floor Guys guys in action in Athy: |

|

| Job: | Henrietta Street, Dublin |

| Smet Supported Partner: |

Tom Togher Plastering Contractors |

| Product: | Bauprocalc KAP 830 |

Related Downloads |

|

DescriptionCASEA Bauprocalc KAP 830 – Hydraulic Lime Based Render was selected for the internal plastering in the renovation of this important historical house in Dublin. Principal building contractor, Lee McCullough Consulting Engineers were tasked with this mammoth renovation project. Smet Supported Partner, Tom Togher was selected for the application of the internal plaster. Project in brief – (text from Lee McCullough Consulting Engineers) Houses #3 and #14 were acquired by Dublin City Council in a bid to arrest their continued dilapidation and prevent collapse. Both houses had been significantly weakened by water ingress and consequent timber decay. The front wall of #3 was in particularly poor condition and significantly cracked. The rear wall of #14 had been weakened by past interventions and was close to the point of collapse. Our brief was to restore structural integrity whilst minimising both cost and structural intervention of these important protected structures. The selected plaster, CE Marked CASEA Bauprocalc KAP 830 is a factory produced hydraulic hardening render/plaster based on lime, specially designed for hand and machine application produced to EN 998-1: 2003. Benefits of CASEA Bauprocalc KAP 830 – Hydraulic Lime Based Render• High water vapour permeability (breathability) It is manufactured from a controlled blend of selected aggregates, hydraulic and building lime to EN 459-1 and other components to give a high-quality rendering product which is suitable for use in external rendering and internal plastering. The unique properties of this render make it suitable for application on low, medium and high-density substrates, for the renovation of old and listed building and ecological new builds. The product’s unique properties such as; high water vapour permeability (breathability), sustainability, and the special composition which allows constant hygrometric exchange between the substrate and the environment, were key drivers in the selection of this lime system. Smet Supported Partner, Tom Togher, Machine Applied Plaster and his team applied the high-quality products to a high-class finish. Another showcase of sympathetic restoration, using top quality lime and lime based products available from Smet Building Products Ltd. Well done to all involved! |

|

| Job | Harold Wood Train Station |

| Client | Capel (CS) Ltd |

| Product | SMET LiteFlo® Lightweight Flowing Screed |

Related Downloads

- TDS SMET LiteFlo® Lightweight Flowing Screed

- Aftercare SMET LiteFlo® Lightweight Flowing Screed

- SMET Floor Screeds and Compounds Product Selector

- SMET LiteFlo Equipment Set Up @GWQ Tower_ Video

Description

Smet Supported Partners, Capel (CS) Ltd, completed the floor screed application of SMET LiteFlo® Lightweight Flowing Screed within the improvement works at Harold Wood Station. A number of improvements were delivered at Harold Wood station in preparation for the new Elizabeth line service, including:

- A new footbridge over the tracks with new staircases

- Three new lifts to provide step-free access to every platform

- Platform extensions to accommodate the new, 200m long Elizabeth line trains

- New platform lighting

- New station signage, help points, customer information screens, and CCTV.

SMET LiteFlo® Lightweight Flowing Screed is a high-quality pumpable, factory-produced, CE marked, self-levelling screed based on calcium sulphate. German-made SMET LiteFlo® is unique because it’s the first pumpable lightweight flowing screed available. Made from specially selected aggregates – means it’s 30% lighter than conventional flowing screeds and can be laid in reduced thicknesses. The screed offers a high yield, 43kg per m2 @ 40mm.

German-made LiteFlo® is unique, in that it’s the first pumpable lightweight flowing screed. Made from specially selected aggregates, makes it 30% lighter than conventional flowing screeds and therefore 70% lighter than traditional sand & cement – ultimately this means less is required per m2. Another plus is that that screed made from Calcium Sulphate has naturally substantially lower embodied carbon emissions than a sand and cement screed. LiteFlo® complies with EN 13813: 2002, is CE-marked, and is available in 27Kg bags or bulk silos.

Have a look at the Northern Builder MagazineTop 5 Liquid Screeds Article. Read about SMET LiteFlo® in the Irish Construction News.

Innovative SMET LiteFlo® is particularly suitable for use in timber-frame builds, suspended timber floors, tower blocks, apartments, and high-rise buildings. SMET demonstrates best practice in construction partnerships – providing a superior level of customer service to their Smet Supported Partners during the installation process.

Whether your job is – self-build, retro-fit, floor renovation or repair, design floor, commercial or shop, sustainable build, historical renovation, ECO build, Lightweight, or an industrial flooring venture – SMET has a flooring compound or ready to use product suitable for your application.