| Job: | W. Gore, new build in Lismullen |

| Smet Supported Partner: | Fast Floor Screed Ltd |

| Product: | Südanit 280 Alpha Hemihydrate Screed |

Related Downloads

Description |

|

| Smet Supported Partner, Fast Floor Screed Ltd, pump-applied self-levelling, Südanit 280 Alpha Hemihydrate Screed in this new development built by W. Gore in Lismullen. This CE marked, self-smoothing, self-levelling screed is the most technologically-advanced floor screed available, complying with the performance requirements of EN 13813.

Südanit 280 Alpha Hemihydrate Screed’s advanced composition means that it reacts with water quickly – providing consistent, reliable drying characteristics and considerably faster drying times – enabling following trades to proceed without delay. The major delivery, completed using their mobile screed factory enabled our Alpha Hemihydrate flooring solution to be installed quickly and efficiently over the entire project. The Fast Floor Screed Mobile Screed Factory – is a unique system. The lorry mounted rigs carry Sudanit 280 Alpha Hemihydrate binder, sand & aggregates and water in separate compartments. The automatic production process ensures materials are precisely weighed, fed to the mixing bin and into the pump for easy, mess-free installation. This ensures the Fast Floor Screed Mobile Screed Factory produces Sudanit 280 Alpha Hemihydrate floor screed to a consistently high quality. Have a look at Fast Floor Screed past projects. The unique bespoke re-load hydraulic screw for sand & aggregates ensures excellent daily output is achieved. Plus, for convenience, there are a number of pre-programmed mix designs to choose from delivering screed floors from C20 to C35. The floor is remarkably quick to walk-on – applied at 500m² per day and walkable within in 6 hours and it’s particularly suitable for use with UFH, fully encapsulating pipes and services – increasing the performance of underfloor heating. Did you know…? This Alpha Hemihydrate Screed can be installed in a heated floating-floor screed construction, uniquely, with the commissioned underfloor heating system up and running @ 25°C?! Smet Building Products Ltd in partnership with Fast Floor Screed Ltd, demonstrate, once again, a superior level of customer service, both pre and aftercare. Whether your job is self-build, retro-fit, floor renovation, design, commercial or an industrial venture – we have a floor compound suitable for you. |

|

| Job: | Self-Build, Castlewellan, Co. Down |

| Client: |

Turley Brothers |

| Product Used: | Turley Bros HydriFlo |

Related Downloads |

|

DescriptionSmet Supported Partner, Turley Bros from Newry, completed the floor screed supply and application of their industry leading flowing HydriFlo Liquid Screed, with application over underfloor heating (UFH) in this self build in Castlewellan. Factory produced to EN 13813, HydriFlo is made with Sudanit 280 binder, supplied by us. Hydri-Flo Liquid Screed is suitable for floors in homes, offices, commercial shops, public buildings and places exposed to similar loads. Smet Building Products Ltd in partnership with Turley Bros, demonstrate best practice in partnerships, yet again, by providing a superior level of customer service in screed flooring. Whether your job is self-build, retrofit, floor renovation, design floor, commercial, shop flooring, sustainable building or an industrial venture – together with our partners, we have a floor compound suitable for any flooring requirement. |

|

| Job: | VHI renovation of Old Church in Abbey Street Dublin |

| Smet Supported Partner: |

B Doherty Screeding Services |

| Product: | Sopro Rapidur® B5 Rapid Drying Screed Binder |

Related Downloads |

|

DescriptionNew floor installation with fast-track – rapid drying floor screed solution, allowing early final flooring installation. SMET supplied Sopro Rapidur® B5 Rapid Drying Screed Binder to Smet Supported Partner, Brendan Doherty Screeding Services, for the flooring solution for the administrative building of the newly renovated VHI HQ in Dublin. B Doherty Screeding Services completed the flooring project on behalf of lead contractor Collen Construction. German made Rapidur® B5 Rapid Drying Screed Binder, is a special polymer-modified binder for particularly economical production of high-strength, rapid-set cement screed – based on DIN 18560 – allowing early floor installation. Rapidur® B5 is suitable for use on heated screeds, bonded screeds, unbonded screeds and floating screeds. This flooring solution is particularly useful for fast-track or tightly scheduled screed laying. The newly laid Rapidur® B5 screed floor is ready to receive floor covering after approx. 3 days – after achievement of moisture content ≤ 1.8 % CM. Sopro Rapidur® B5 is supplied in 25kg bags, with 40 bags per pallet. SMET delivers another innovative, showcase flooring solution to their Smet Supported Partners. Sopro Rapidur® B5 is supplied to our professional partners in 25kg bags, with 40 bags per pallet. SMET delivers another innovative, showcase flooring solution to their Smet Supported Partners. Click the link to see a showcase of jobs recently completed by expert screeder, Brendan Doherty Screeding Services. The Sunday Business Post tells us: ‘The VHI is planning to develop new headquarters on top of the former Scots Presbyterian church hall on Abbey Street in Dublin city centre. The church will become the main entrance and foyer for the office building, while the church hall and former lecture theatre will have “a new lightweight glass and metal exoskeleton structure” of up to seven storeys built above and around them. Plans for the development, which have been submitted to Dublin City Council, were published on archiseek.com, an online discussion forum for architects. Designed by McCauley Daye O’Connell, the new building will integrate with the existing VHI offices and create a U-shaped building around the church, which will be refurbished’. The Sunday Business Post |

|

| Job: | Lidl Bucksburn Aberdeen |

| Main Contractor: | AFS Scotland Ltd |

| SMET Products Used: |

Bauprotec 850 M – Lime Cement Render Bauprotec RHS – Multi-Purpose Render |

Related Downloads |

|

DescriptionSmet Supported Partner, AFS Scotland Ltd, machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render and as Finish Coat: Mineral Finish Coat K. As Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render with the addition of Bauprotec SLP for plinths. The Internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. The LIDL render specification, available from SMET consists of:Bauprotec 850 M is a factory produced Lightweight Lime Cement Render, specially designed for machine or hand application produced to EN 998-1: 2010 and is CE Marked. Bauprotec RHS is a CE Marked, factory produced highly polymer-modified render specially designed for hand and machine application produced to EN 998-1: 2010. Mineral Finish Coat – K is a CE marked, factory produced mineral based, high-quality finish-coat render, specially designed for hand and machine application to EN 998-1, 2010. Bauprotec SLP is a CE Marked, factory produced Lightweight Sand & Cement Render specially designed for hand and machine application produced to EN 998-1: 2010. Why choose SMET?The special render properties; lightweight, low thermal conductivity, high yield and Smet Supported Partner superior technical backup, are key factors in choosing SMET. SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job click to contact SMET. All LIDL spec SMET Render System products are available directly from awarding winning supplier, Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|

| Job: | Lidl Luton Road, Dunstable |

| Main Contractor: | WS Gewebebau GmbH |

| SMET Products Used: |

Bauprotec 850 M – Lime Cement Render Bauprotec RHS – Multi-Purpose Render |

Related Downloads |

|

DescriptionSmet Supported Partner, WS Gewebebau GmbH machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render and as Finish Coat: Mineral Finish Coat K. As Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render with the addition of Bauprotec SLP for plinths. The Internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. The LIDL render spec, available from SMET consists of:Bauprotec 850 M is a factory produced Lightweight Lime Cement Render, specially designed for machine or hand application produced to EN 998-1: 2010 and is CE Marked. Bauprotec RHS is a CE Marked, factory produced highly polymer-modified render specially designed for hand and machine application produced to EN 998-1: 2010. Mineral Finish Coat – K is a CE marked, factory produced mineral based, high-quality finish-coat render, specially designed for hand and machine application to EN 998-1, 2010. Bauprotec SLP is a CE Marked, factory produced Lightweight Sand & Cement Render specially designed for hand and machine application produced to EN 998-1: 2010. Why choose SMET?The special render properties; lightweight, low thermal conductivity, high yield and Smet Supported Partner superior technical backup, are key factors in choosing SMET. SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job click to contact SMET. All LIDL spec SMET Render System products are available directly from awarding winning supplier, Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|

| Job: | Maldron Hotel Swimming Pool Renovation, Portlaoise, Co. Laois. |

| Smet Supported Partner: |

Precision Building Services – Mark Pemberton |

| Product: | Sopro Rapidur® B5 Rapid Drying Screed Binder

Sopro RAM 3 (454) Renovation and Levelling Mortar Sopro GD 749 Universal Floor and Wall Primer Sopro DSF® 523 Tanking Membrane Sopro VF HF 420 – VarioFlex® High Strength Flexible Tile Adhesive Sopro’s No. 1 Flexible Tile Adhesive Sopro DE 014/015 Sealing Corners Sopro FKM® XL 444 – Extra Light Weight Tile Adhesive Sopro FEP 508 Sopro DBF-638 Racofix 818 |

Related Downloads

|

|

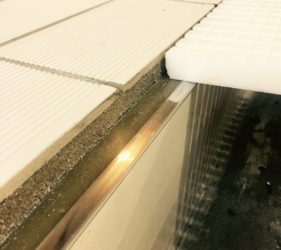

DescriptionSMET supplied Smet Supported Partner, Precision Building Services (Mark Pemberton), for the renovation of the Maldron Hotel Swimming Pool, Portlaoise, Co. Laois. A total area of Floor screed @ 140m² | Wall tiling @125m² | Floor tiling @ 140 m² was completed. New floor installation with fast-track – rapid drying floor screed solution, using Sopro Rapidur® B5 Rapid Drying Screed Binder, a fast-setting screed which was laid to falls prior to waterproofing and tiling providing an early completion. German-made Rapidur® B5 Rapid Drying Screed Binder is a special polymer-modified binder for particularly economical production of high-strength, rapid-set cement screed – based on DIN 18560. Rapidur® B5 is suitable for use on heated screeds, bonded screeds, unbonded screeds, and floating screeds. This flooring solution is particularly useful for fast-track or tightly scheduled screed laying. The newly laid Rapidur® B5 screed floor is ready to receive floor covering after approx. 3 days – after the achievement of moisture content ≤ 1.8 % CM. Sopro Rapidur® B5 is supplied in 25kg bags, with 40 bags per pallet. Sopro Rapidur® B5 was installed directly on top of Merlin Barrier Coat wet on wet. The screed was ready for waterproofing/tiling after 3 days. This system was also used to repair the Jacuzzi’s surrounding walls prior to waterproofing, tiling, and grouting. Sopro RAM 3 levelled the deck area (3-60mm) between the drainage channel edge and pool perimeter movement joint. Sopro RAM 3 was bonded with Sopro GD 749. Sopro No.1 tile adhesive created a notched finish on the walls of the drainage channel for Sopro RAM 3 to also level out. Finer repairs (0-10mm) on the channel wall were repaired with Sopro Repadur 10s. As the Sopro Repadur 10s is a highly polymer-modified, there was no need for priming bar pre-dampening with water. Sopro DSF 523 Tanking Membrane was applied in 3 coats (2mm dried film thickness) to waterproof the deck screed, repaired drainage channels and surrounding shower area walls (pipe collars were also installed). Sopro DBF-638 pre-folded tape, Sopro DE 014/015 Internal/External tape and Racofix 818 were also used in the overlapping and waterproofing of the wall/floor joints in the channel. Capillary Seal (Sopro EPG 522: Fine Sand: Coarse Sand – 1:1:1) was installed around the perimeter of the pool where the drainage channel meets the deck screed. A 45-degree cut was made into the screed behind the RAM 3 wall repair and filled with the Capillary Seal mix, preventing pool water leeching into the screed and causing screed erosion. Sopro PUK 503 polyurethane tile adhesive bonded the mosaic tiles to the jacuzzi once the repairs and waterproofing had finished. Sopro VF HF 420 fast setting high strength tile adhesive was used to bond the deck tiles. These tiles were then grouted with Sopro Titec Plus grout. Sopro No.1 tile adhesive was also used to bond tiles to the drainage channel walls. Sopro FKM XL 444 tile adhesive was used to bond tiles to the surrounding walls and grouted with Sopro DF 10 Flexible designer grout. Sopro Sanitary Silicone sealed the pool perimeter movement joint after a 10mm packing foam cord was pressed into the joint. Sopro FEP 508 epoxy grout was used to grout between where the perimeter edge tile met the capillary seal to create a full water-tight grout area. ClickSMET TANKING & TILING E BOOK

SMET delivers another innovative, showcase waterproofing and tiling swimming pool solution to their Smet Supported Partners. |

|

Check out another swimming pool tanking and tiling we supplied to John Sisk & Son, a full package of Sopro Tanking & Tiling, for the completion of 6,000m2 Quartzite Floor Tiling and 1,500 m2 Waterproofing & Tanking and completion of Wall Tiling.

| Job: | LIDL Lurgan |

| Main Contractor: | McCaliion Group |

| SMET Products Used: | Bauprotec 850 M – Lime Cement Render |

Related Downloads |

|

DescriptionLocal Smet Supported Partner, McCallion Group, machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render, and as Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render. The internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. The Irish LIDL render spec, available from SMET consists of: Bauprotec 850 M is a factory produced Lightweight Lime Cement Render, specially designed for machine or hand application produced to EN 998-1: 2010 and is CE Marked. Bauprotec RHS is a CE Marked, factory produced highly polymer-modified render specially designed for hand and machine application produced to EN 998-1: 2010.

The special render properties; lightweight, low thermal conductivity, high yield and Smet Supported Partner superior technical backup, are key factors in choosing SMET. Here’s the McCallion Group in action: Mc Callion Group – Recent Lidl Projects from Mc Callion Group on Vimeo. SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job – contact SMET on. All LIDL spec SMET Render System products are available directly from Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|

| Job: | Lidl Boston |

| Main Contractor: | Adston Construction |

| SMET Products Used: |

Bauprotec 850 M – Lime Cement Render Bauprotec RHS – Multi-Purpose Render |

Related Downloads |

|

DescriptionLocal Smet Supported Partner, Adston Construction commenced construction of the new Lidl Boston store in July 2017. Adston Construction machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render and as Finish Coat; Mineral Finish Coat K. As Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render with the addition of Bauprotec SLP for plinths. The Internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. The LIDL render spec, available from SMET consists of: Bauprotec 850 M is a factory produced Lightweight Lime Cement Render, specially designed for machine or hand application produced to EN 998-1: 2010 and is CE Marked. Bauprotec RHS is a CE Marked, factory produced highly polymer-modified render specially designed for hand and machine application produced to EN 998-1: 2010. Mineral Finish Coat – K is a CE marked, factory produced mineral based, high-quality finish-coat render, specially designed for hand and machine application to EN 998-1, 2010. Bauprotec SLP is a CE Marked, factory produced Lightweight Sand & Cement Render specially designed for hand and machine application produced to EN 998-1: 2010. The special render properties; lightweight, low thermal conductivity, high yield and Smet Supported Partner superior technical backup, are key factors in choosing SMET. SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job – contact SMET on. All LIDL spec SMET Render System products are available directly from Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|

| Job: | Lidl Dover Kent |

| Main Contractor: | Adston Construction |

| SMET Products Used: |

Bauprotec 850 M – Lime Cement Render Bauprotec RHS – Multi-Purpose Render |

Related Downloads |

|

DescriptionLocal Smet Supported Partner, Adston Construction machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render and as Finish Coat; Mineral Finish Coat K. As Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render with the addition of Bauprotec SLP for plinths. The Internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. The LIDL render spec, available from SMET consists of: Bauprotec 850 M is a factory produced Lightweight Lime Cement Render, specially designed for machine or hand application produced to EN 998-1: 2010 and is CE Marked. Bauprotec RHS is a CE Marked, factory produced highly polymer-modified render specially designed for hand and machine application produced to EN 998-1: 2010. Mineral Finish Coat – K is a CE marked, factory produced mineral based, high-quality finish-coat render, specially designed for hand and machine application to EN 998-1, 2010. Bauprotec SLP is a CE Marked, factory produced Lightweight Sand & Cement Render specially designed for hand and machine application produced to EN 998-1: 2010. The special render properties; lightweight, low thermal conductivity, high yield and Smet Supported Partner superior technical backup, are key factors in choosing SMET. SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job – contact SMET on. All LIDL spec SMET Render System products are available directly from Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|

| Job: | Lidl Haverhill Cambridge |

| Main Contractor: | Adston Construction |

| SMET Products Used: |

Bauprotec 850 M – Lime Cement Render Bauprotec RHS – Multi-Purpose Render |

Related Downloads |

|

DescriptionLocal Smet Supported Partner, Adston Construction machine applied the LIDL External Render System onto Poroton blocks externally using as Base Coat: Bauprotec 850 M – Lightweight Lime Cement Render and as Finish Coat; Mineral Finish Coat K. As Key Coat: Change of substrate concrete/steel pillar/Poroton block or mass concrete and insulated plinths: Bauprotec RHS Multi-Purpose Render with the addition of Bauprotec SLP for plinths. The Internal Render System specification onto Poroton blockwork consists of a base of Coat: Bauprotec 850 M, Lightweight Lime Cement Render, sponge floated in warehouse areas and skim finished in sales areas. Key Coat: Change of substrate concrete/steel pillar/Poroton block: Bauprotec RHS is used. The LIDL render spec, available from SMET consists of: Bauprotec 850 M is a factory produced Lightweight Lime Cement Render, specially designed for machine or hand application produced to EN 998-1: 2010 and is CE Marked. Bauprotec RHS is a CE Marked, factory produced highly polymer-modified render specially designed for hand and machine application produced to EN 998-1: 2010. Mineral Finish Coat – K is a CE marked, factory produced mineral based, high-quality finish-coat render, specially designed for hand and machine application to EN 998-1, 2010. Bauprotec SLP is a CE Marked, factory produced Lightweight Sand & Cement Render specially designed for hand and machine application produced to EN 998-1: 2010. The special render properties; lightweight, low thermal conductivity, high yield and Smet Supported Partner superior technical backup, are key factors in choosing SMET. SMET is committed to delivering consistently superior quality, German-made Render Systems to Lidl Plastering and rendering/plastering contractors across the UK and ROI. If you’d like to speak to us about your Lidl job – contact SMET on. All LIDL spec SMET Render System products are available directly from Smet Building Products Ltd, who ensures the contractor has a superior level of technical back up in the machine application of the LIDL specification. |

|