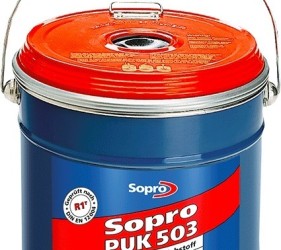

Sopro PUK 503 PU Adhesive

Sopro PUK 503 PU Adhesive is a two-component, light-coloured polyurethane reaction resin adhesive, meeting R2 T requirements to DIN EN 12004, for laying and bonding of ceramic tiles, natural and cast stone units, and resin-bonded tiles. The product is particularly suitable for use with wood-based, gypsum-based and metal substrates. Meets enhanced requirements in terms of tensile and shear adhesion strengths, elasticity and water tightness on critical substrates.

For use with earthenware, stoneware and fully vitrified stoneware tiles, ceramic split tiles and split tile fittings, clinker floor tiles, glass and sintered glass mosaic; calibrated natural and cast stone units, resin-bonded tiles. Also for use with kitchen worktops, prefabricated building interiors, metal stairs, lifts, floor and wall heating systems of sheet steel construction and shipbuilding.

Sopro PUK 503 PU Adhesive is suitable for use with moisture-sensitive substrates such as wood-based and gypsum products; Concrete*, lightweight concrete*, aerated concrete*, cement and eminently hydraulic lime renders*, masonry cement*, plane, flush-jointed masonry* (no composite masonry), cement screeds*, gypsum, gypsum plasterboard and gypsum fibreboard drywall panels, gypsum planks, fibre-cement board, decorative high-pressure laminate, calcium sulphate-based and magnesium oxychloride (magnesite) screeds, mastic asphalt screeds, cement-bonded and resin-bonded particleboard, existing tile, terrazzo, natural and cast stone coverings, existing PVC finishes, polyester (GRP), parquet flooring, plywood, metal surfaces.

* These substrates are required to be primed using Sopro Epoxy Primer EPG 522 and sand scatter blinded using either Sopro fine or coarse quartz sand.

Related Downloads

![]() Smet Professional Tiling Systems Brochure

Smet Professional Tiling Systems Brochure

Featured Benefits of Sopro PUK 503 PU Adhesive

• For walls and floors

• For indoor and outdoor use

• With ship approval

• Suitable for use with moisture-sensitive substrates

• Working life: approx. 45 minutes

• Meeting R2 T requirements to DIN EN 12004

Technical Details of Sopro PUK 503 PU Adhesive

| Colour | Light Grey |

| Mixing Ratio (water only) | (for partial quantities) A:B = 8:1 parts by weight |

| Mixing | The two components are supplied in the correct mixing ratio (component A 5.33 kg + component B 0.67 kg).Pierce (flat) container with activator several times using awl or screwdriver so as to ensure all activator is emptied out.Let Component B run into Component A and mix for min. 3 minutes to achieve a homogeneous, streak and bubble-free consistency using mixing attachment at slow speed (7 rps). Transfer prepared mix to clean container and thoroughly restir. Do not apply directly from original supplied container! |

| Consistency of mix | Smooth paste |

| Bed thicknessMinimum thickness for floor heating systems | Up to 5 mm2 mm compact adhesive bed |

| Coverage | Approx. 1.5 kg/m² per mm coat thickness |

| Maturing Time | N/A |

| Pot Life | Approx. 45 minutes |

| Walkable/Grouting | After approx. 12 hours respectively after setting of PU-adhesive |

| Loading | After approx. 1 day; in commercial facilities after approx. 2 days; in areas subject to high wet exposure after approx. 2 days, for underwater areas after approx.2 days, in conjunction with floor heating after approx. 2 days |

| Application Temperature | From +10 °C up to +25 °C (substrate, air, metal) |

| Tools | Mixing attachment, notched trowel with suitable serration: 3 – 4 mm for tesserae, 4 – 6 mm for wall and floor tiles, 6 – 8 mm for heavy ceramics and profiled tile |

Bucket 6kg (components A+B)

SMET has a wide range of Professional Tiling systems, including, High-Strength adhesive, Flexible Adhesive, and Large-Format adhesives, primers, multi-purpose primers, sealers and tools available for your tiling needs.