| Job: | Maldron Hotel Swimming Pool Renovation, Portlaoise, Co. Laois. |

| Smet Supported Partner: |

Precision Building Services – Mark Pemberton |

| Product: | Sopro Rapidur® B5 Rapid Drying Screed Binder

Sopro RAM 3 (454) Renovation and Levelling Mortar Sopro GD 749 Universal Floor and Wall Primer Sopro DSF® 523 Tanking Membrane Sopro VF HF 420 – VarioFlex® High Strength Flexible Tile Adhesive Sopro’s No. 1 Flexible Tile Adhesive Sopro DE 014/015 Sealing Corners Sopro FKM® XL 444 – Extra Light Weight Tile Adhesive Sopro FEP 508 Sopro DBF-638 Racofix 818 |

Related Downloads

|

|

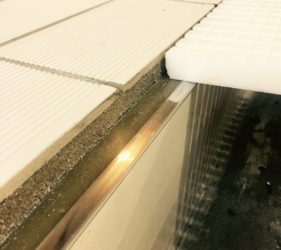

DescriptionSMET supplied Smet Supported Partner, Precision Building Services (Mark Pemberton), for the renovation of the Maldron Hotel Swimming Pool, Portlaoise, Co. Laois. A total area of Floor screed @ 140m² | Wall tiling @125m² | Floor tiling @ 140 m² was completed. New floor installation with fast-track – rapid drying floor screed solution, using Sopro Rapidur® B5 Rapid Drying Screed Binder, a fast-setting screed which was laid to falls prior to waterproofing and tiling providing an early completion. German-made Rapidur® B5 Rapid Drying Screed Binder is a special polymer-modified binder for particularly economical production of high-strength, rapid-set cement screed – based on DIN 18560. Rapidur® B5 is suitable for use on heated screeds, bonded screeds, unbonded screeds, and floating screeds. This flooring solution is particularly useful for fast-track or tightly scheduled screed laying. The newly laid Rapidur® B5 screed floor is ready to receive floor covering after approx. 3 days – after the achievement of moisture content ≤ 1.8 % CM. Sopro Rapidur® B5 is supplied in 25kg bags, with 40 bags per pallet. Sopro Rapidur® B5 was installed directly on top of Merlin Barrier Coat wet on wet. The screed was ready for waterproofing/tiling after 3 days. This system was also used to repair the Jacuzzi’s surrounding walls prior to waterproofing, tiling, and grouting. Sopro RAM 3 levelled the deck area (3-60mm) between the drainage channel edge and pool perimeter movement joint. Sopro RAM 3 was bonded with Sopro GD 749. Sopro No.1 tile adhesive created a notched finish on the walls of the drainage channel for Sopro RAM 3 to also level out. Finer repairs (0-10mm) on the channel wall were repaired with Sopro Repadur 10s. As the Sopro Repadur 10s is a highly polymer-modified, there was no need for priming bar pre-dampening with water. Sopro DSF 523 Tanking Membrane was applied in 3 coats (2mm dried film thickness) to waterproof the deck screed, repaired drainage channels and surrounding shower area walls (pipe collars were also installed). Sopro DBF-638 pre-folded tape, Sopro DE 014/015 Internal/External tape and Racofix 818 were also used in the overlapping and waterproofing of the wall/floor joints in the channel. Capillary Seal (Sopro EPG 522: Fine Sand: Coarse Sand – 1:1:1) was installed around the perimeter of the pool where the drainage channel meets the deck screed. A 45-degree cut was made into the screed behind the RAM 3 wall repair and filled with the Capillary Seal mix, preventing pool water leeching into the screed and causing screed erosion. Sopro PUK 503 polyurethane tile adhesive bonded the mosaic tiles to the jacuzzi once the repairs and waterproofing had finished. Sopro VF HF 420 fast setting high strength tile adhesive was used to bond the deck tiles. These tiles were then grouted with Sopro Titec Plus grout. Sopro No.1 tile adhesive was also used to bond tiles to the drainage channel walls. Sopro FKM XL 444 tile adhesive was used to bond tiles to the surrounding walls and grouted with Sopro DF 10 Flexible designer grout. Sopro Sanitary Silicone sealed the pool perimeter movement joint after a 10mm packing foam cord was pressed into the joint. Sopro FEP 508 epoxy grout was used to grout between where the perimeter edge tile met the capillary seal to create a full water-tight grout area. ClickSMET TANKING & TILING E BOOK

SMET delivers another innovative, showcase waterproofing and tiling swimming pool solution to their Smet Supported Partners. |

|

Check out another swimming pool tanking and tiling we supplied to John Sisk & Son, a full package of Sopro Tanking & Tiling, for the completion of 6,000m2 Quartzite Floor Tiling and 1,500 m2 Waterproofing & Tanking and completion of Wall Tiling.

| Job | Private ICF Home, Carlingford, Co Louth |

| Smet Supported Partner | Eddie McGee Plastering |

| Products | CASEA Bauprotec RHS

Sopro GD 749 Universal Floor and Wall Primer 1.5mm Acrylic Render in White |

Related Downloads

- TDS Acrylic Finish Coat Render

- TDS Sopro GD 749 Universal Floor and Wall Primer

- TDS CASEA Bauprotec RHS – Multi-Purpose Render

Description

High-quality, solvent-free Acrylic Finish Coat Render, was selected for the façade finish in this Self-Build ICF construction in Co Louth. Smet Supported Partner, Eddie McGee Plastering, applied the synthetic resin (acrylic) based final coat at 1.5 mm on a base of Bauprotec RHS, primed with Sopro GD 749 Universal Floor and Wall Primer, with associated beading in place. Acrylic Finish Coat Render complies with DIN 18558 – POrg.1 and satisfies the requirements for synthetic resin render in DIN 18550, Part 1. The Render properties, such as vapour permeability, the waterproof qualities and availability in an even textured – K or grooved/drag render finish, along with a choice of a wide range of standard, RAL or NCS colours; were the key factors in selecting this façade system.

ISO 9001 accredited Smet Building Products Ltd, demonstrating, once again – best practice in supporting their selected partners in Render Systems Solutions. Contact info@smet.ie

| Job | Private ICF Home, Graiguennamanagh, Co Kilkenny |

| Smet Supported Partner | John Curran Plastering |

| Products Used | CASEA Bauprotec RHS, Sopro GD 749 Universal Floor and Wall Primer, and 1.5mm Acrylic Render |

Related Downloads

- TDS Acrylic Finish Coat Render

- TDS Sopro GD 749 Universal Floor and Wall Primer

- TDS CASEA Bauprotec RHS – Multi Purpose Render

Description

High quality, solvent-free Acrylic Finish Coat Render, was selected for the façade finish in this this Self-Build ICF construction in Co Kilkenny. Smet Supported Partner, John Curran Plastering, applied the synthetic resin (acrylic) based final coat at 1.5 mm on a base of SHG Bauprotec RHS, primed with Sopro GD 749 Universal Floor and Wall Primer. Acrylic Finish Coat Render complies with DIN 18558 – POrg.1 and satisfies the requirements for synthetic resin render in DIN 18550, Part 1. The Render properties, such as: vapour permeability, the waterproof qualities and availability in an even textured – K or grooved/drag render finish, along with a choice of a wide range of standard, RAL or NCS colours; were the key factors in selecting this façade system.

ISO 9001 accredited Smet Building Products Ltd, demonstrating, once again – best practice in supporting their selected partners in Render Systems Solutions. Contact info@smet.ie