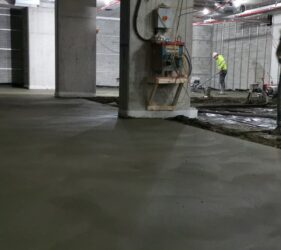

B Doherty Mobile Screed Factory_at the Boston Sidings Final Pour_EB5 Rapid Drying Floor Screed

| Job: | Boston Sidings Grand Canal Dock Final Pour |

| Smet Supported Partners: Main Contractor: |

B Doherty Screeding Service

Collen Construction |

| Product: | Rapidur® EB5 Rapid Drying Floor Screed |

DescriptionWe supplied our Rapidur® EB5 additive to Smet Supported Partner, B Doherty Screeding Mobile Screed Factory. On behalf of Collen Construction, using their Mobile Screed Factory, with the help of Laser-Guided, Screed Robot, they supplied polymer-modified Rapidur® EB5 Rapid Drying Sand / Cement screed with fibres at 75mm. This ensured a fast turnaround with UFH being commissioned 3 days later at the Grand Canal Dock Boston Sidings. Have a look at these wonderful pictures.

|

|

• Factory Produced On-Site

• Rapid Drying and Fibre Reinforced

• Allowing early use of screed

• Allowing early floor covering installations

• Bonded, Unbonded, and Floating Floor Screed Constructions

• Suitable For Underlayment In Wet Areas

• BS 8204-1 ISCR Categories A, B, and C

SMET assists in delivering another innovative, showcase flooring solution to their Smet Supported Partners.