Plumbing and Heating Magazine | Joris Smet explains benefits of UFH with Screed

This month’s Plumbing & Heating Magazine features include underfloor heating. An article by Joris Smet explains the benefits of self levelling calcium sulphate screeds in combination with underfloor heating.

Not read it yet? Please click link to read article UFH by Joris Smet to read the article online, or visit www.plumbingmag.com

Smet delivers unrivalled performance with CA Screeds

Self-levelling calcium sulphate screeds (CA screeds) have long been heralded as superior in internal applications due to proven technical advantages.

CA screeds have minimum shrinkage and therefore do not curl; they fully encapsulate the underfloor heating pipes, have a high thermal conductivity and can be installed in significantly reduced thicknesses. This allows thicker insulation to be used under the screed resulting in better thermal insulating values or U-values. Consequently CA screeds gain heat rapidly and transport heat to the surface of the screed into the air, resulting in an efficient response to room temperature changes.

RESEARCH

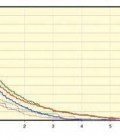

Independent research carried out by MPA (Material-Prüf-Anstalt) in Stuttgart, Germany shows (Graph 1) that much higher surface temperatures are achievable in CA screeds than in conventional sand and cement screeds. It further shows, for example, a temperature of 30°C is reached much more quickly in SLCSS than in conventional sand and cement screeds at the same thickness and is even quicker at reduced thicknesses.

How does this demonstrate superior performance? After heating the various screeds for a time, a 35mm CA screeds reaches the highest temperature, while a 45mm conventional sand and cement screed remains at the lowest temperature.

Due to the higher temperatures gained in CA screeds it takes similar time to cool the screeds down, even at reduced thicknesses. After three to four hours there is no difference in cooling down (Graph 2). It is apparent CA screeds gain heat quickly and heat to a much higher temperature at the surface. Also, because CA screeds can be used in much thinner applications (typical >40mm) than conventional sand and cement screeds (typical >60mm), thicker insulation can be utilised, which will further insulate the heated screed, allowing the screed to retain its heat for longer.

Therefore, CA screeds are more energy efficient, responding quickly to changes in room temperatures. Traditional thick screeds cannot respond as efficiently to, for example, solar gain in the afternoon or when a fireplace is lit in the winter. This ineffective response (heating/cooling) often leads to a room being too hot or too cold, a problem eliminated by application of a superior self-levelling calcium sulphate screed.

Smet Building Products Ltd is Ireland’s leading specialist supplier of calcium sulphate binders for use in the manufacture of calcium sulphate flowing screeds. Screeds are available nationwide through Smet supported partners.

Graph 1

KEY:

F35 – 35mm self-levelling calcium sulphate screed

F45 – 45mm self-levelling calcium sulphate screed

K45 – 45mm conventional sand and cement screed

Source: MPA (Material-Prüf-Anstalt)

Graph 2 illustrates the cooling of various screeds after underfloor heating is switched off (running at a water temperature of 35°C or 45°C) and allowed to cool down.

Graph 2

KEY:

F34 – 35mm self-levelling calcium sulphate screed @ 45°C and 35°C

F41 – 45mm self-levelling calcium sulphate screed @ 45°C and 35°C

K42 – 45mm conventional sand and cement screed @ 45°C and 35°C

Source: MPA (Material-Prüf-Anstalt)